The explosion-proof MX-X forklift truck guarantees safe warehouse processes in hazardous materials warehouses

Chemion

Industry: logistical services for the chemical industry and associated sectors

Company: 1,000 employees. Locations: Leverkusen, Dormagen, Krefeld-Uerdingen and Duisburg

Challenges: Inventory management of inflammable substances, possible explosive dust or gas mixtures. 200 pallets moved per day.

STILL products: Special explosion-proof version of the STILL MX-X order picker truck in accordance with ATEX Directive 2014/34/EU

Sparks and static discharge must not be allowed to occur in places where inflammable materials can form explosive dust or gas mixtures during inventory management. To protect against the occurrence of explosions, the apparatus, operation and maintenance of the vehicles and equipment used are subject to strict regulations. A STILL MX-X order picker forklift truck in a special explosion-proof design was recently commissioned at the hazardous materials warehouse of Chemion Logistik at CHEMPARK Leverkusen.

Chemion Logistik: the specialist for hazardous material

Since 2001, Chemion Logistik has operated as an independent site logistics specialist and specialist in the handling of a large number of hazardous materials and storage classes for the chemical industry. With an annual turnover of almost 700,000 pallets at CHEMPARK sites in Leverkusen, Dormagen, Krefeld-Uerdingen and the two field warehouses in Duisburg, Chemion Logistik is perfectly equipped for chemical industry cargo orders with some 70,000 pallet bays in block shelving, racking, very narrow aisle shelving and open depots – both in terms of solids and liquids.

Chemion hazardous materials warehouse at CHEMPARK Leverkusen

More than 6,100 pallets can be stored in the bays of the 51 shelving rows at Chemion Logistik’s hazardous materials warehouse. 200 pallets are handled on a daily basis in both goods receipt and goods issue. In the 25 high shelving aisles, a STILL explosion-proof MX-X VNA truck transports barrels and cans with hazardous liquids and big bags and bagged goods with chemical solids to storage locations. Hubert Kubitza, Chemion Logistik cargo logistics manager at CHEMPARK Leverkusen states: “In accordance with the German Federal Immission Control Act (BimSchV), our pallet storage is certified for particularly hazardous substances. Leaking solvents from the bottled basic chemicals can evaporate and combine with the oxygen in the air to form an explosive mixture. The spaces in which such atmospheres arise must therefore be specifically identified as explosive areas. The hazardous materials warehouse is equipped with catch basins in case of leaks, and has an open construction without external walls on the front and rear to disperse explosive vapours.”

Explosive atmospheres are divided into areas

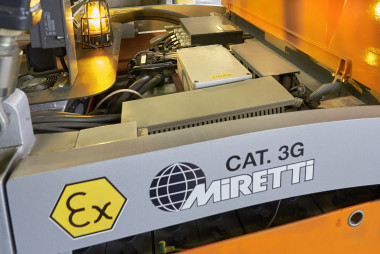

Statutory provisions regulate the manufacture and operation of explosion-proof industrial trucks. These are based on criteria relating to the type of explosive atmosphere. The guideline for users is ATEX Directive 2014/34/EU. For example, hazard zones for explosive gas mixtures are divided into three classes. There should be no effective ignition sources in these areas. This includes electric forklift trucks which are not specially encapsulated. Moreover, electric forklift trucks may only operate in an explosive atmosphere if their maximum surface temperature remains below the ignition temperature of the surrounding explosive mixture. Six temperature classes have been defined to facilitate assessment. Within these classes, equipment is categorised according to the maximum temperature that can be reached. The manager of Chemion Logistik, Adrian Ksoll, who is responsible for the use and rental of industrial trucks, adds: “In our hazardous materials warehouse, explosive gas concentrations occur rarely and only briefly. Consequently, for STILL’s MX-X, equipment category 3G with explosion-proof modifications and temperature class 4 are required for the category 2 hazard area. The maximum radiation temperature of STILL’s MX-X therefore must not exceed 135°C. Almost 2,200 industrial trucks are available in our rental pool, just 500 of which are explosion-proof. The manufacture and operation of explosion-proof forklift trucks is highly complex. In Europe, only a few companies rent out such equipment.”

Explosion-proof solutions

Almost all of STILL’s electrically driven forklift trucks are available as an explosionproof version. Industrial trucks that must meet requirements on protection against explosions are developed by STILL and Miretti, the specialist in such conversions. The entire conversion is designed with the pre-determined usage profile in mind. Then, all the truck components which can trigger explosions with sparks, voltage or electrostatic charge are encapsulated or covered with appropriate materials. All connections are specially protected to prevent any sparking or discharging. The stainless steel coated prongs prevent sparks from being generated in the event of shock and friction contact. The mast operates pneumatically rather than electrically. To avoid explosive deflagration, the resulting oxyhydrogen gas is discharged separately in the battery. The special explosion-proof version also includes a personal safety system enabling pedestrians and MX-X trucks to work alongside each other, a flashing light, a battery adapter and connector, two working headlights and cab heating. The brakes and hydraulics are encapsulated in accordance with explosion protection provisions. The avoidance of electrostatic charge is a key factor both in the choice of upholstery for the driver’s seat and in the construction of the interior trim with conductive rubber mats. The impellers, drive wheel and guide rollers are also antistatic, meaning that they are made of conductive material. Static charges caused by mechanical forced guidance are also discharged. The cockpit display also displays warning messages about the surface temperature of the MX-X.

The MX-X: guaranteed driving comfort and safety

In the ergonomic driver’s cab of the MX-X, the thermostatically controlled heating and ventilation system ensure a comfortable working environment. The sliding door on the left side enables comfortable entry and exit. The large panoramic windows on the front and sides provide a clear view of the fork prongs and storage locations in the hazardous materials warehouse. The LED headlights to the left and right of the overhead guard can be switched on to illuminate the shelves. The height and inclination of the operating panel can be adjusted optimally and ergonomically for standing or seated operation. Based on a contact-free sensor, the integrated two-hand scan reduces operator fatigue. Using the intelligent load chart, the Optispeed driver assistance system combines the advantages of optimised truck movements for greater load capacity, comfort and safety. Depending on the fork height, the permissible load weight is displayed dynamically on the LCD display. The emergency exit via the roof window with its abseiling system completes the safety equipment package. “Moreover, we have a reserve truck in the unlikely event that the MX-X should break down,” adds Hubert Kubitza of Chemion Logistik.

Summary

In areas with an explosive atmosphere, non-explosion-proof industrial trucks may

constitute an ignition source owing to high surface temperatures, shock or friction

sparks and electrostatic charges. STILL therefore supplies an explosion-proof

version of almost all its electric forklift trucks. Nevertheless, it should be noted that care and attention from all involved is also vital when it comes to handling hazardous

substances.