Intralogistic systems

Manage with more intelligence,

work with more efficiency

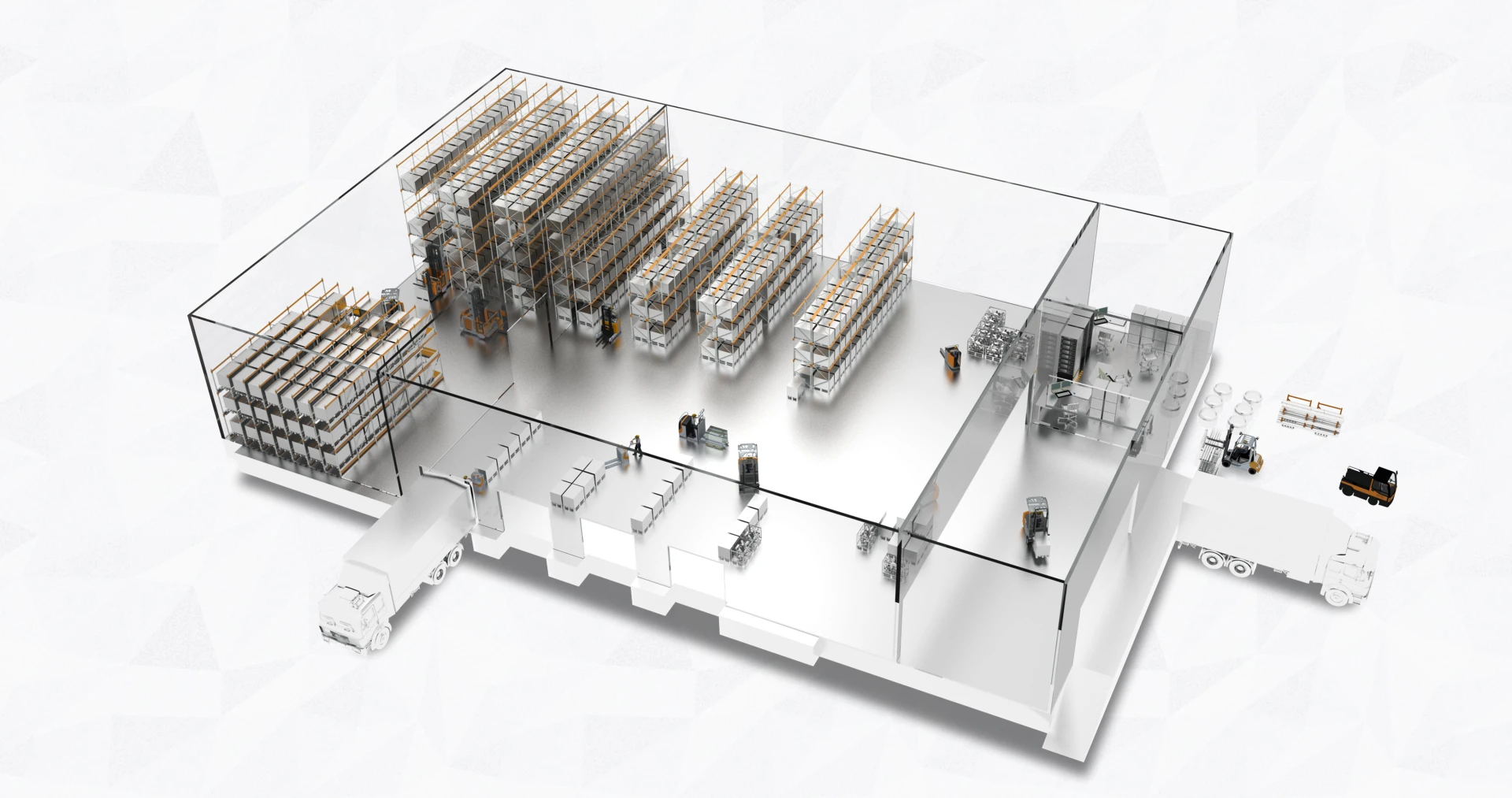

There is no simple solution to complex problems. At first sight, the interaction of intralogistics processes with a large number of interlinked systems seems to make it difficult to optimise processes in the warehouse. However, for us exactly this combination of the individual processes is the ideal basis to make use the full potential.

Our warehouse trucks, products and services harmonise with each other so that we are able to offer you a comprehensive, tailored and highly flexible solution. On top of this, all components are flexible enough to adapt perfectly to existing structures and systems.

We actively shape the future of our costumers' intralogistics - from target-oriented consulting to implementation.

Goal-oriented solutions for your challenges

STILL can look back on almost 100 years of experience in the field of warehouse technology, intralogistics and forklift manufacturing. We are experts in intralogistics, original thinkers and pioneers, and we are actively shaping the future of intralogistics for our customers – from target-orientated consultancy to implementation.

Specifically, this means that we only propose solutions that we are certain we will be able to implement, and which will continue to work in the future. In order to ensure this we visit our customers on-site at the warehouse and production areas, speak directly with the employees there and closely examine all the relevant processes.

We obtain a comprehensive understanding of your individual challenges and consequently develop a customised solution for you to achieve outstanding cost- effectiveness. We work with full vigour, place great emphasis on honesty and transparency and communicate clearly and directly to you exactly what our consultants are doing. We thus create a solid basis for a trusting collaboration to your utmost satisfaction.

And this is how we work

Data acquisition

Outstanding analysis is generally based on high-quality datasets.

Analysis

We use techniques such as grouping, sorting, compressing and filtering to obtain logistical findings using the prepared data; this then serves as the basis for planning.

Optimisation

We use techniques such as grouping, sorting, compressing and filtering to obtain logistical findings using the prepared data; this then serves as the basis for planning.

Conceptualisation

Our goal is to minimise your transport, warehouse and handling costs.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

Use the contact form

Write to us – we will get back to you

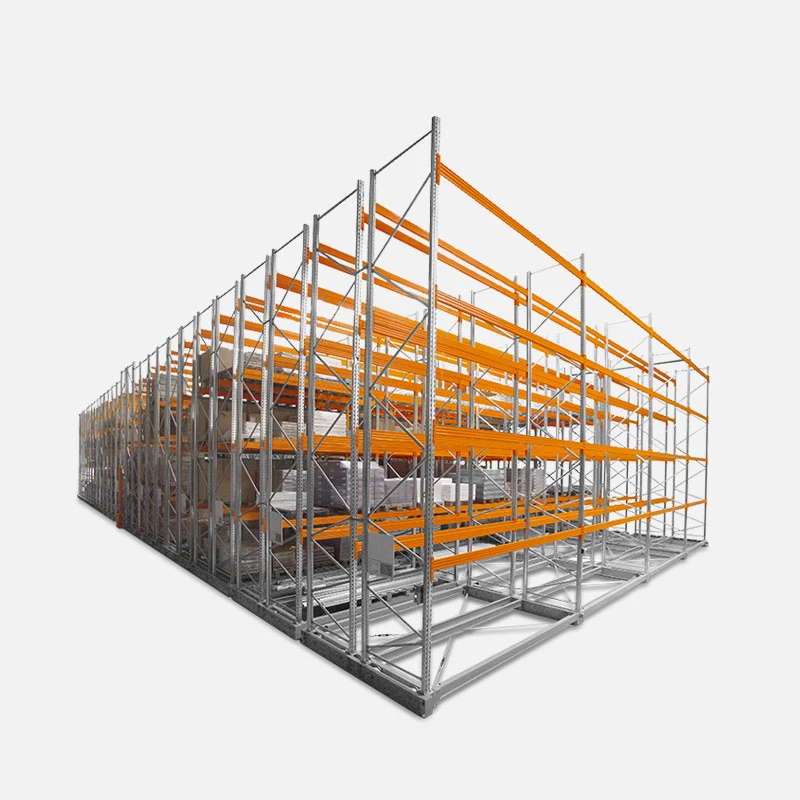

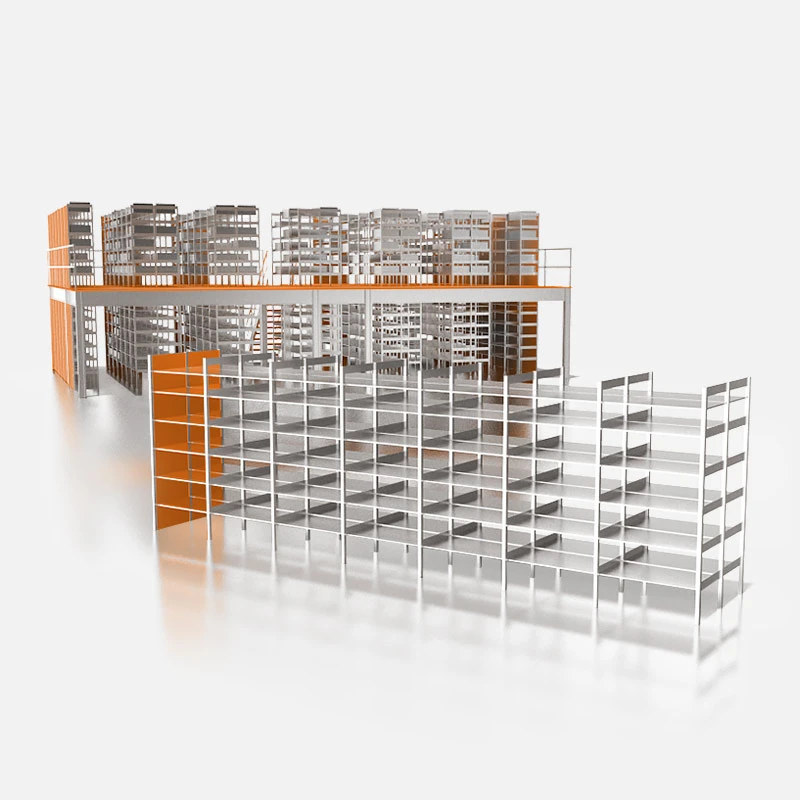

STILL rack systems are an elementary component of intelligent intralogistics. High efficiency is best achieved by an effective layout of the warehouse.

STILL racking systems, an elemantary component of intelligent intralogistics.

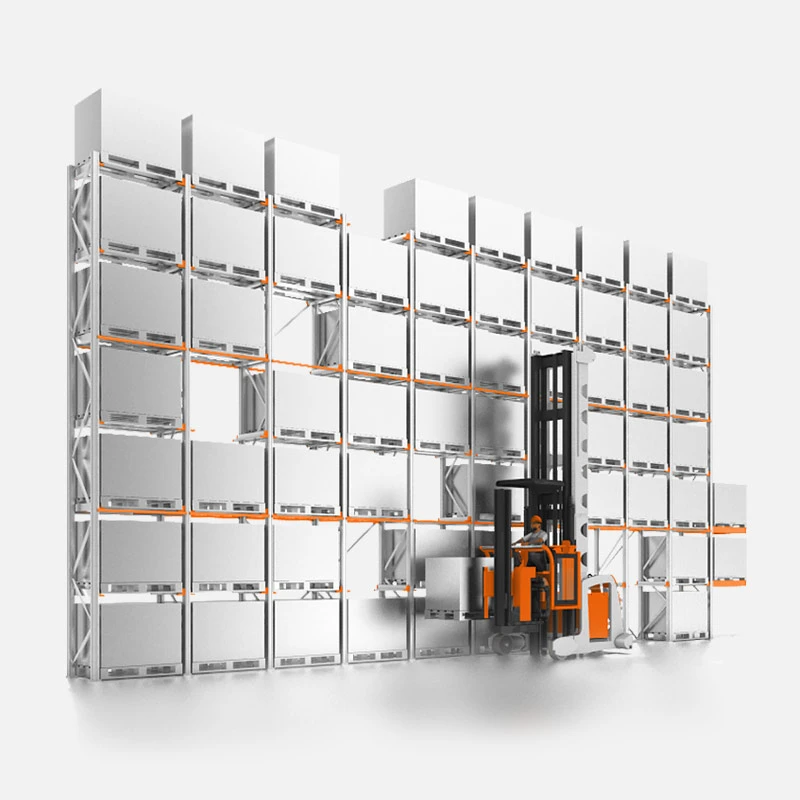

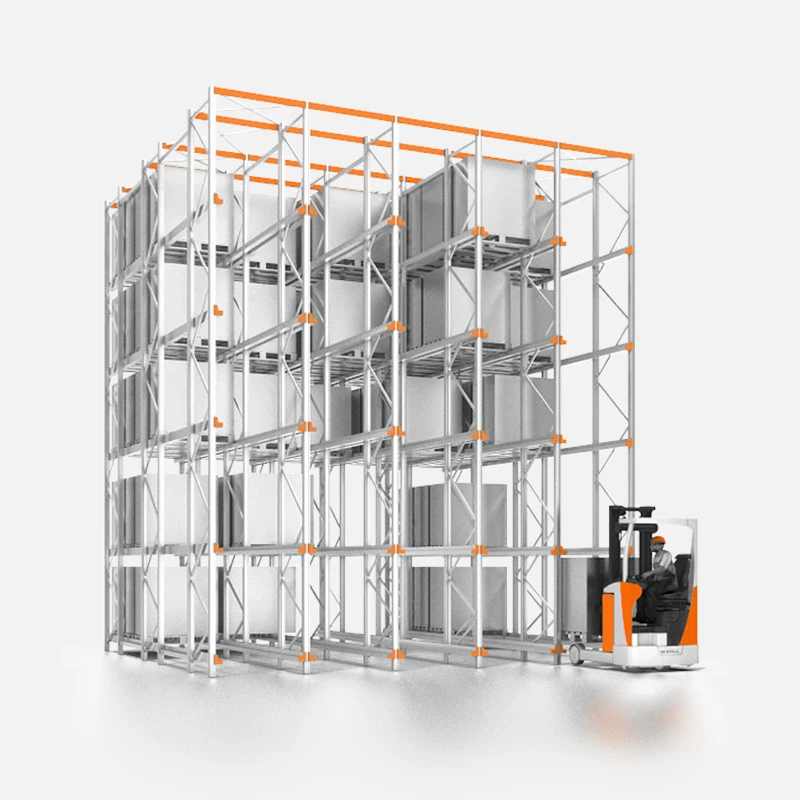

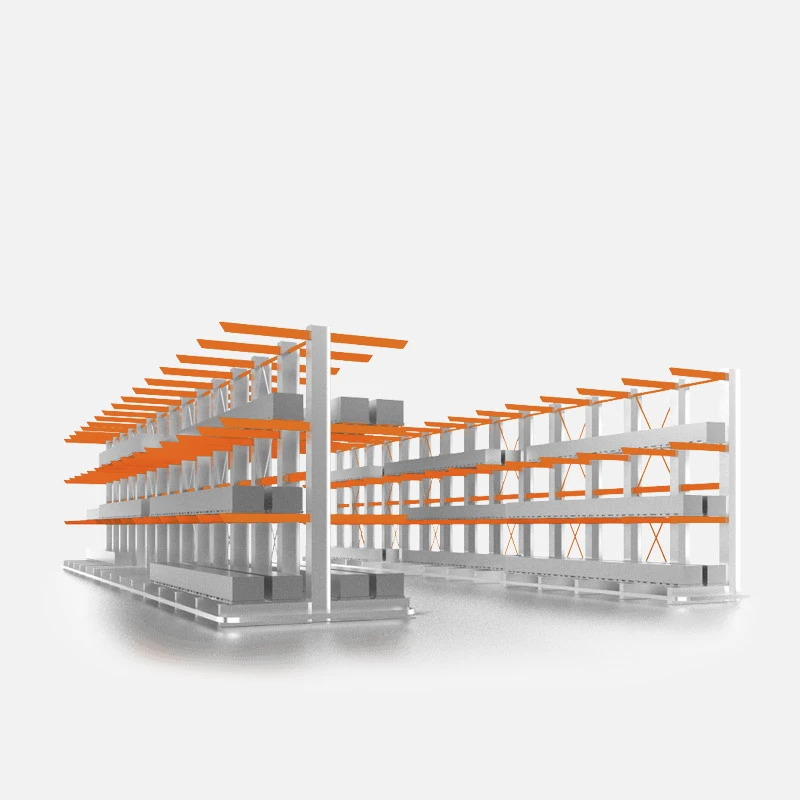

High efficiency is best achieved by an effective layout of the warehouse. As a full range supplier STILL offers a broad range of industrial racking systems including static installations such as pallet, drive-in or cantilever racks and dynamic systems, e.g., drive through and moving racks as well as moving platforms.

Mobile racking

Maximum density in small spaces.

Shelving

The solution for unpacked goods and small parts

Platform

Efficient and individual use of high building spaces.

Rack Inspection

Regular rack inspections help to avoid accidents.

Our racking systems

Pallet racking

Just as variable as your requirements.

Drive-in and drive-through racking

For compact storage.

Pallet shuttle systems

For maximum turnaround speed.

Cantilever racking

Tidy and easy storage of bulky goods

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

Use the contact form

Write to us – we will get back to you

Benefit from STILL automation systems and optimize your internal logistics processes with extra safety, process excellence, availability and economic feasibility.

Thanks to its comprehensive product range STILL iGo helps to automate nearly the entire material flow in a warehouse, regardless of whether its newly designed or already being used. The range of solutions and expansion possibilities allows not only for tailored improvements to existing conditions such as narrow or wide aisles, but the total automation of vertical and horizontal transport as well. Automated STILL vehicles cover the entire in-house material flow at your warehouse - from the receipt of goods to final shipment to your partners.

iGo systems

Different storage situations require individual solutions. iGo systems offers you a perfectly adjusted combination of different series produced trucks and corresponding technology, including the installation of all components. For analysis, planning and implementation,rely on needs-based automation and ultimate efficiency through the selection of optimally adjusted technologies. Various types of navigation allow the trucks to move independently through the warehouse. At the same time, you always remain flexible, because all forklift trucks can also be operated manually at any time.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

Use the contact form

Write to us – we will get back to you

Perfectly suited for complex requirements

Use the STILL warehouse management system (WMS) to control and effect every movement of material in the warehouse individually, including goods received, warehouse control and order picking just as well as tour planning and despatch. In these processes every information such as load carrier information and information about the article like batch number, best-before-date and serial number and the respective storage strategies are considered in order to provide material punctually, according to the demand and to make best use of the space inside the warehouse. Besides all of this the system allows to administer empties and annual or permanent stock taking.

MMS Stock management system

Use the STILL warehouse management system (WMS) to control and effect every movement of material in the warehouse individually, including goods received, warehouse control and order picking just as well as tour planning and dispatch.

MMS Transport and truck control system

The transport/truck control system (TCS) controls the movement of the trucks in the warehouse taking various criteria into account.

MMS Information System

The STILL MMS information system keeps you informed about all relevant data, such as status of current orders or individual articles.

MMS Hardware

In the context of the STILL material flow management system, the term hardware refers to all the components forming a system together with the software.

Intelligent System Architecture

Subordinate and super ordinate systems such as ERP systems or conveyors, moving racks and other hardware components, can be easily integrated into the STILL MMS.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

Use the contact form

Write to us – we will get back to you

Optimizing your fleet

It is always important to maintain an overview; especially for larger fleets. STILL can help with fleet monitoring and offers long term fleet management. The more extensive, older or diverse a fleet is, the higher its optimization potential; as is the desire to outsource it or its management so that you can concentrate fully on the challenges of running your actual business. The Solution: The FleetManager made by STILL.

Fundamental Goals:

- Inexpensive modernization of the fleet

- Calculation of savings potential

- Creation of an individualized fleet management concept

- Fleet optimization

- Optimization of the fleet's structures and the integration of ground conveyors in the flow of materials

FleetManager 4.x

Using STILL's FleetManager™, you decide who can use which vehicles, record information regarding deployment, accidents or workloads and utilization of the vehicles.

Fleet Consultation

STILL offers a long-term fleetmanagement through fleet takeover.

We are there for you.

Do you have any questions or would you like personal advice?

Then you've come to the right place. Our team of experts will take care of your request - individually and quickly.

Call a consultant

We are there for you – Monday to Friday

Use the contact form

Write to us – we will get back to you